ALBANY, N.Y. — Governor Andrew Cuomo announced Thursday that 12 companies will share nearly $7 million in state incentive funds to start making COVID-19 equipment and supplies in anticipation of a possible second wave of the virus.

Four of those companies are in Western New York.

The grant money will help alleviate product shortages due to supply chain issues than can sometimes lead to unfair pricing practices.

"During the pandemic, the nation has learned a hard lesson about not having a supply chain for vital supplies based here at home in the U.S. and as a result we had to scour the globe for live-saving products that are mainly manufactured overseas," Cuomo said. "That won't happen again in New York.

"We are building the infrastructure needed for the future and by supporting local companies' pivot to new areas of production, we will be in a better position to avoid supply and demand issues and secure the items we need both quickly and at reasonable prices."

In March, the governor asked companies across the state to consider retooling their operations, with state help, in order to make critically needed COVID-19 supplies such as masks, ventilators, gloves, gowns and face shields.

The local companies assisting in the state efforts are:

- KSL Diagnostics, Inc. based in Williamsville

- Shatkin, F.I.R.S.T., LLC based in Amherst

- Starline USA based on Grand Island

- You First Services based in Buffalo

2 On Your Side spoke with some of the executives from those businesses Friday evening. KSL Diagnostics and Biomedical CEO Kevin Lawson told 2 On Your Side that as a private clinical lab firm they came to understand how they could fill a void in the supply chain.

"Reagents have been in short supply and specimen collection materials have been in short supply since the very beginning," Lawson said. "Recognizing the need for the specimen collection materials we started manufacturing some of those ourselves."

Lawson also pointed out their lab, which has ties to UB and its research programs, has a specific testing results goal which can be crucial for patients and health care providers.

"We're striving to be able to meet and maintain three days or less test turnarounds," Lawson said.

The state indicates its test sample collection kits are being produced in Western New York for distribution to nursing homes, ambulatory surgery centers, hospitals and national laboratories to help meet the critical need for testing. KSL will invest $2.1 million with plans to hire 36 additional employees to produce over 10,000 test sample kits per week and scale its testing capacity.

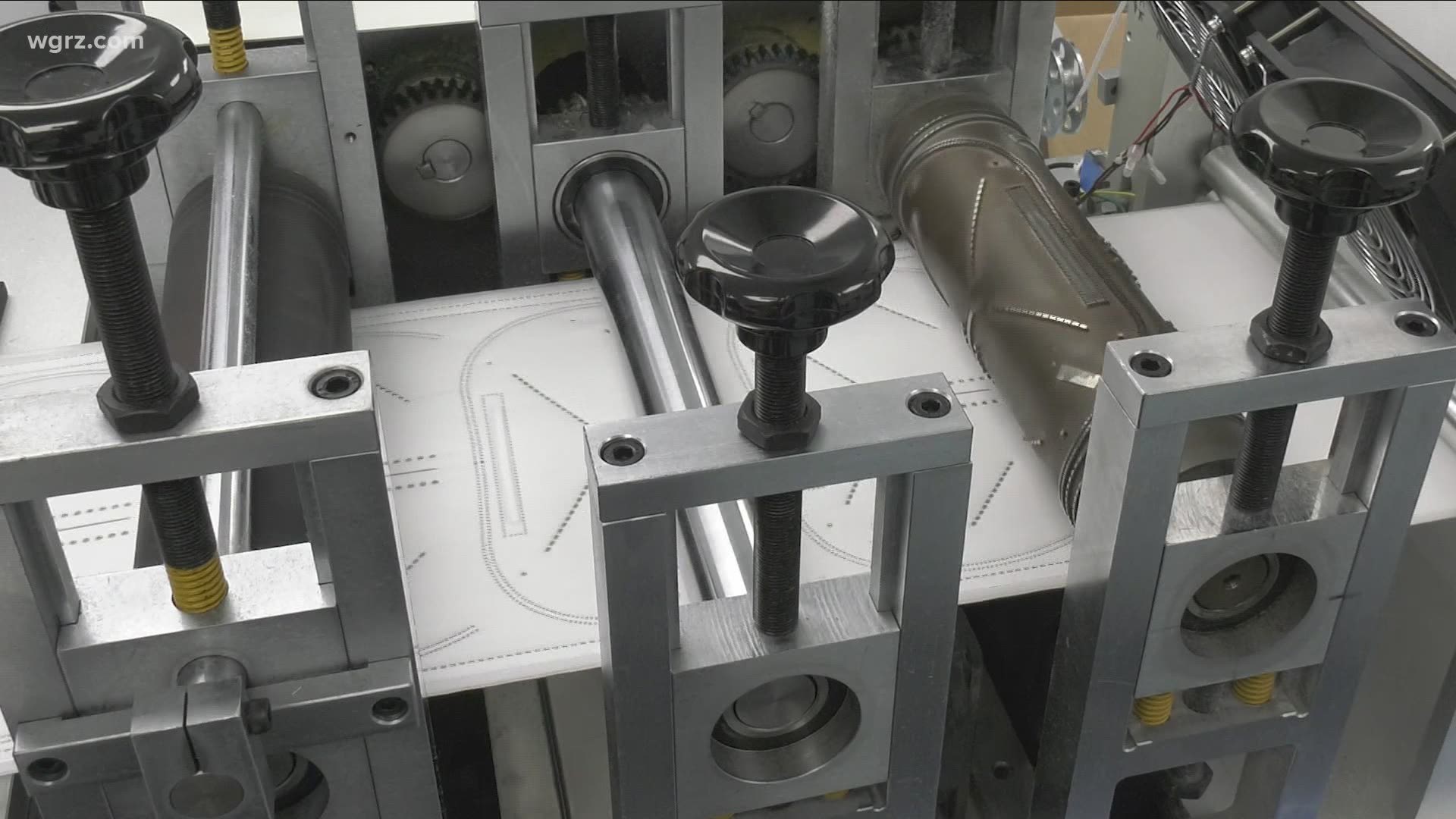

Dr. Todd Shatkin is a well known local dentist who has specialized in dental implants. But his dental supply firm Shatkin F.I.R.S.T. has also now shifted to producing the much sought after N95 respirators or masks for health care professionals and others.

"We now have a total of six machines... two mask making machines, two headband machines and two packaging machines," Shatkin said. "And we've got about 50 employees that are working. We've got two shifts going and we could add another."

The state adds that Shatkin F.I.R.S.T. has invested more than $1 million to date, hired at least 30 people, manufactured more than 400,000 N95 respirators, and recently obtained that second machine to be able to manufacture millions of N95 respirators. They hope to turn out over 50,000 masks per week.

"I'm very proud to be able to be involved in this - with helping the United States, with helping the country to kinda combat this pandemic," Shatkin said.

2 On Your Side also spoke with You First Service CEO Dr. Satish Sharma and VP of Engineering Dr. John Lordi. They told us about their hi-tech compressor system known as SteriSpace, an infectious disease containment and patient isolation technology licensed through SUNY Research Foundation and SUNY Buffalo. You could say it will actually "cook" COVID-19 to kill it along with numerous other viruses like anthrax and SARS.

"What's particularly important now is with COVID-19, which is a virus, that it's been known to be susceptible to destruction by heat," Lordi said.

You First Services Research and Development, based in Cheektowaga, has seen its system tested by the Defense Department and used in field hospitals and similar applications. Now their hope is to offer the system to schools, hospitals and similar settings.

"This will lead to significant expansion as this technology will be needed," Sharma said.

You First Services is investing more than $1 million to get the first five sites installed and plans to add up to 20 full time and part time employees to its current staff of 40.

Starline USA in Grand Island manufactures promotional products and safety equipment such as eyewear and head protection. The state points out, "StarlineUSA's laser capacity for producing promotional items, lent itself well to retooling for the COVID-19 crisis producing face shields and the company was also already selling PPE-related products in the promotional market. The total project cost is $485,000, and the company plans to produce 1,080,000 face shields."

"Many of the world's premier and most innovative companies are in New York State," said Empire State Development Acting Director & CEO-designate Eric Gertler.

"ESD's support for these businesses not only answers Governor Cuomo's call for homegrown industries to assist with the state's efforts to combat the coronavirus but reflects the investment that is being made to strengthen New York's manufacturing sector, enhance a diverse, dynamic private sector partner that can adapt quickly to new market opportunities, and continue its record of smart growth as we reopen and grow statewide."